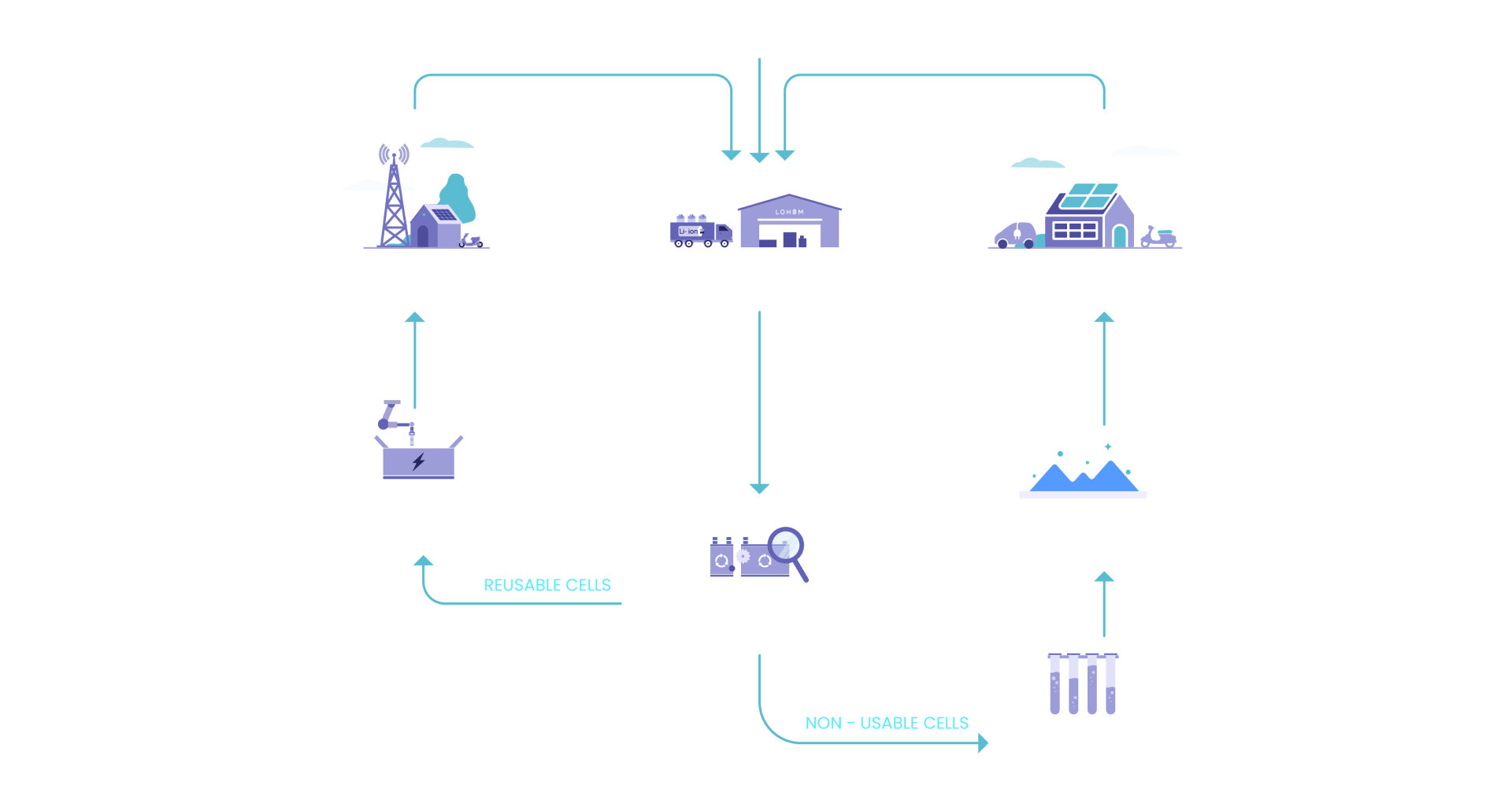

High-performance Lithium ion batteries for powering e-mobility

To charge up the future of sustainable eMobility and sustain the Electric Vehicle battery revolution, LOHUM’s scalable platform design gives you the freedom to avail custom Lithium ion battery solutions for your specific requirements, future-proofing yourself, your fleets, and your logistics.

Key Features: LOHUM Electric Vehicle Battery Technology

- Battery status SOC & SOH estimation with state-of-the-art Kalman Filter algorithm prepared by HPPC test of cells.

- Scalable Lithium ion battery modules for a flexible approach to fully custom battery designs with in-house BMS and IP68 waterproofing.

- Passive cell balancing and safety controls to detect and intuitively purge over or under voltage, overcharge and short circuit.

- Thermal management diagnostics to control heat transfer and maintain the Electric Vehicle battery pack at optimum temperatures.

- Live and remote tracking, with 4G IOT data monitoring (optional add-on).

- Audio-visual alarm system for any inappropriate temperature rise inside the battery pack.